Discover Exactly How a Membrane Switch Enhances Sturdiness and Capability in Devices

Checking Out the Advantages of Membrane Layer Switches in Modern Electronic Tools

The integration of membrane switches over right into modern electronic tools presents a number of compelling advantages that merit consideration. Their layout flexibility permits a high level of customization, satisfying certain branding and useful needs throughout different sectors. Coupled with their remarkable durability, these buttons withstand difficult atmospheres, hence expanding their functional lifespan. The cost-effectiveness of membrane switches over settings them as a practical alternative for suppliers looking for to optimize their item offerings. The full effect of these functions on customer experience and operational efficiency warrants further examination.

Layout Flexibility

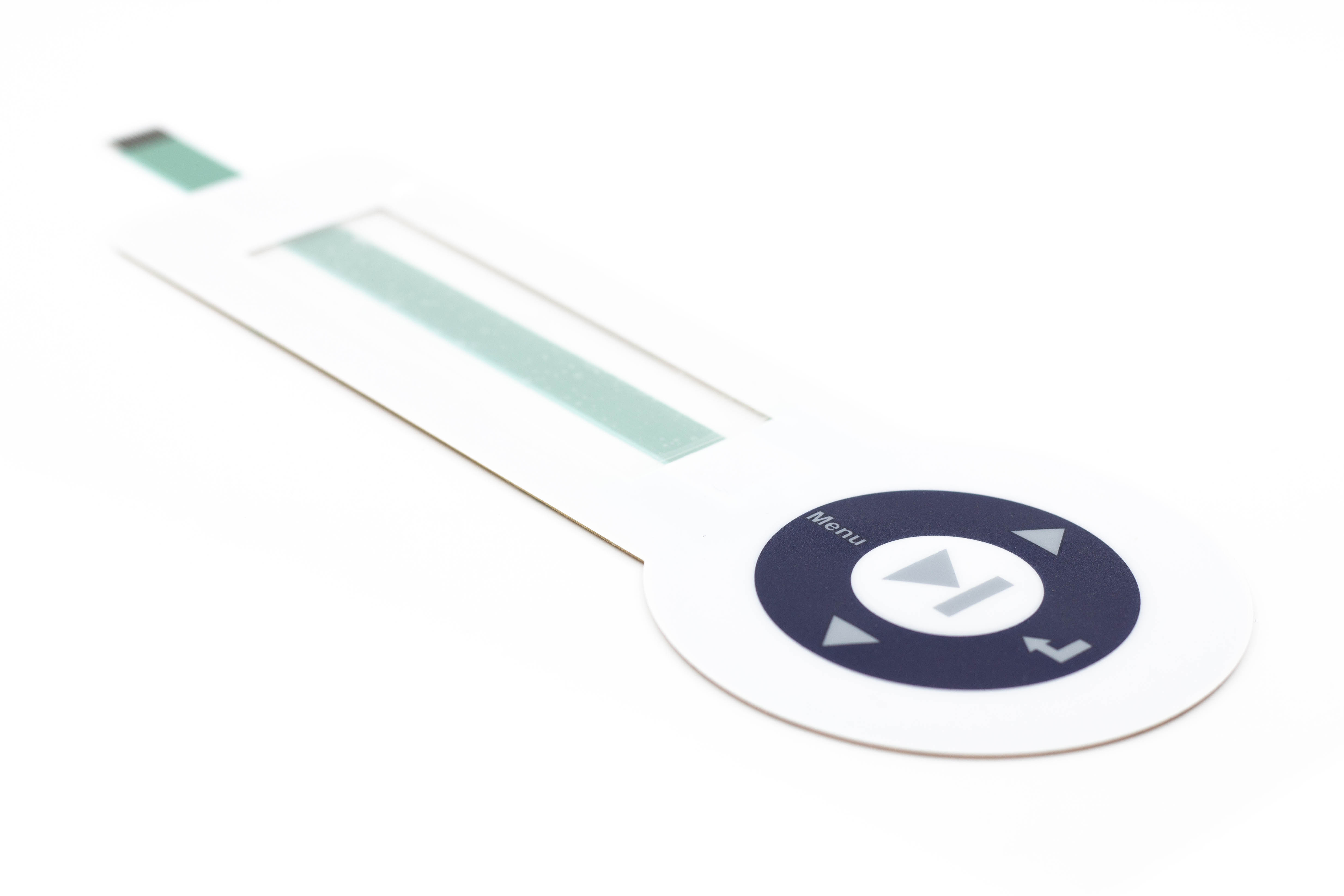

Style flexibility is an essential advantage of membrane buttons, allowing suppliers to develop personalized interfaces that meet certain functional requirements. This flexibility is vital in an era where individual experience and capability are vital. Membrane buttons can be developed in numerous shapes, sizes, and shades, enabling for aesthetic integration right into varied digital gadgets.

The published graphics can be customized to match branding, while the tactile responses can be gotten used to improve individual communication. Furthermore, membrane buttons can include numerous layers, enabling functions such as backlighting and safety overlays, which add to both visual appeal and functionality.

Suppliers can additionally utilize various products, such as polyester or polycarbonate, to line up with particular application demands. This convenience reaches the setup of the button layout, allowing the combination of several functions within a solitary interface.

The capability to personalize not only boosts the use of electronic gadgets however likewise permits the incorporation of sophisticated innovations, such as capacitive touch. As an outcome, membrane buttons are an optimal option for a wide range of applications, varying from medical tools to consumer electronic devices, guaranteeing that customer needs are continually fulfilled.

Resilience and Durability

Resilience and long life are critical variables that boost the appeal of membrane buttons in contemporary electronic tools. These buttons are designed to hold up against difficult atmospheres, consisting of exposure to moisture, dust, and different chemicals. The durable products utilized in their building, such as polyester and polycarbonate, contribute considerably to their resistance versus abrasion and impact, ensuring that they maintain capability also under strenuous conditions.

Moreover, membrane buttons are inherently sealed, stopping contaminants from penetrating the interior elements. This closed building and construction not just prolongs the life-span of the buttons yet additionally decreases the frequency of maintenance and substitutes, which is a necessary facet for suppliers and end-users alike.

One more advantage is their capacity to sustain extensive cycles of procedure without deterioration in performance (Membrane Switch). This particular makes them particularly appropriate for applications needing regular usage, such as medical gadgets, commercial machinery, and consumer electronic devices

Cost-Effectiveness

In addition, membrane layer buttons are generally generated using inexpensive materials and procedures. Their lightweight style not only decreases shipping expenses but also enables for less complicated combination into digital devices. This can result in more savings in making costs, as streamlined setting up procedures minimize labor and time demands.

In addition, the integral simplicity of membrane switch layouts usually indicates fewer components are needed compared to conventional mechanical switches. This reduction partly not just lowers manufacturing expenses yet likewise reduces factors of failing, improving dependability and efficiency.

In markets where budget restraints are vital, such as customer electronics and commercial applications, the cost-effectiveness of membrane layer switches over becomes particularly beneficial. Their capacity to provide regular performance at a lower lifecycle expense positions them as a sensible option for contemporary digital equipment. In general, investing in membrane switches can cause considerable long-lasting cost savings for companies and customers.

Personalization Options

Personalization choices for membrane layer buttons are substantial, permitting producers to tailor these parts to satisfy details application requirements. Among the primary benefits of membrane switches is their versatility in style. Manufacturers can pick from a range this content of materials, including polyester, polycarbonate, and acrylic, each offering unique benefits in terms of toughness and looks.

Moreover, membrane layer buttons can be personalized in various sizes and shapes to fit distinct gadget arrangements. This flexibility includes the consolidation of various colors, graphics, and textures, allowing brand names to keep their aesthetic identity while improving individual experience (Membrane Switch). In addition, producers can integrate tactile comments functions, such as printed tricks or varying actuation pressures, to enhance usability

Custom circuit styles allow for particular performances, allowing producers to produce switches that cater exactly to their product's demands. On the whole, these extensive customization choices make membrane changes an engaging selection for modern-day electronic devices.

Applications in Different Industries

Membrane buttons discover comprehensive applications throughout a variety of industries, showing their flexibility and capability in many setups (Membrane Switch). In the medical care market, they are generally used in clinical tools, such as client screens and analysis tools, where dependability and convenience of cleansing are vital. Their sealed design assists avoid contamination, making them suitable for environments that need strict hygiene requirements

In the vehicle industry, membrane buttons play a critical role in control panels and dashboards, supplying an user-friendly user interface for chauffeurs. The tactile responses and customizable features boost user experience while guaranteeing toughness against resonances and ecological factors.

Moreover, in industrial applications, membrane buttons are used in machinery control systems, enabling for direct and efficient individual interaction. With their adaptability, membrane layer switches offer a have a peek here durable solution that satisfies the diverse needs of today's technology-driven markets, verifying essential for both functionality and visual appeal.

Final Thought

In verdict, membrane layer changes offer significant benefits in modern electronic equipment due to their style adaptability, sturdiness, and cost-effectiveness. The lightweight nature of membrane switches over more adds to lowered shipping prices and simplicity of combination.